Guardian Bikes to Build Automated Bike Factory in USA.

Every year, approximately 11 million kids bikes are purchased in the United States. 10.5 million out of the 11 million (96%) are imported from China.

Guardian Bikes mission is to make the safest kids bikes, sold direct to your door, with an incredible customer experience. We do that through first principles innovation across a variety of areas —from our patented award winning SureStop brake technology, to our RideSizer software, to our proprietary packaging and 99% assembled home delivery.

Today, we are announcing a HUGE step in our mission, and our biggest innovation yet. We are building a highly automated factory to make Guardian Bikes right here in the USA.

At Guardian, we have always been focused on the quality, durability, and safety of our bikes, as your child's bike riding experience is and always will be our top priority. Unfortunately, most other kids bikes today are built like cheap toys. They are built to be disposable, rather than being built for safety. 96% of all the kids bikes sold today are imported from China, another few percent are imported from other Asian countries, and virtually none are made in the USA.

Guardian’s vision is to challenge this status quo in every way. We’ve said NO to disposable unsafe kids bikes, and instead, make the safest bikes, ones kids LOVE to ride, and soon will be built right here in the USA.

An un-sustainable model:

The model of importing complete bikes from China has to evolve. It is not environmentally sustainable, and it's not a system that makes sense. Think of it this way: only about 350 bikes fit in a 40 foot shipping container. Meaning every year, 30,000 40 ft trailers full of kid's bikes take long carbon emitting journeys by diesel trucks, ships, and trains around the world, through warehouses and distribution centers, until the bikes eventually are delivered to the floor of a US retailer.

Each individual container’s journey to the USA emits about as much C02 as an average passenger vehicle emits over a year!

Then, once these bikes make it on their journey to the store, millions of individual consumers then drive their cars to these stores to pick up the bikes and drive home, adding even more to the carbon footprint of every single one of these bikes.

By moving production of our bikes to the USA, and then fulfilling our bikes straight from our US factory floor direct to your door, we begin to create a sustainable supply chain system, which allows us to not only be a Guardian for the kids in your family with the safest bikes available for them, but also be a Guardian for the future of the planet they will grow up on.

This transition to US production will happen in several phases.

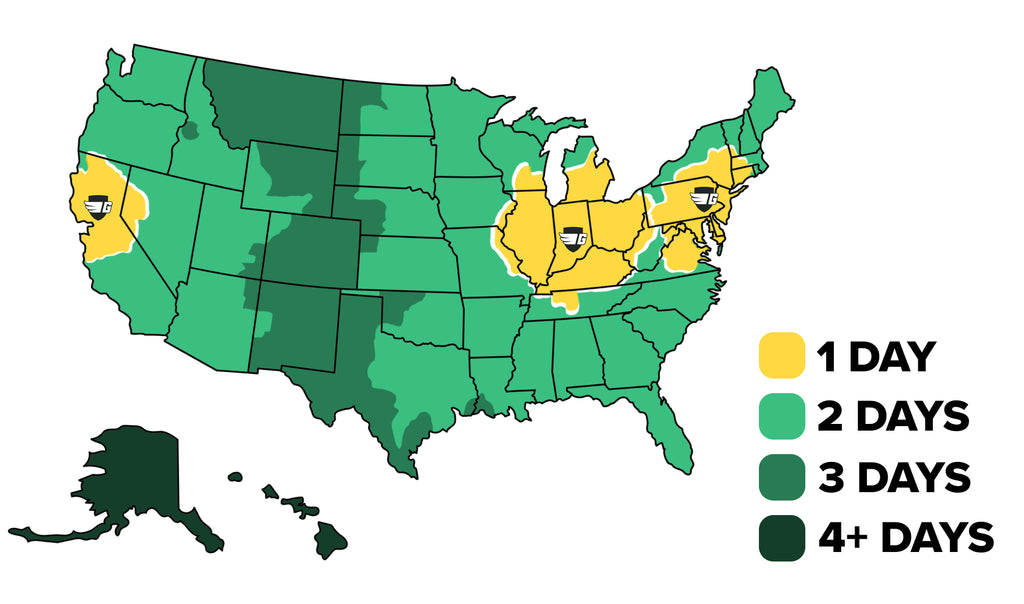

Phase 1 will involve final assembly of parts and frames, which will begin in June of this year. We have chosen our first Guardian Factory location to be in the midwest. We will eventually build multiple factories and become even more localized. The shorter the path from the factory floor to your door, the better.

Wheel Truing Robot automatically tightens bikes spokes for a perfectly straight wheel during testing of Guardian Bikes US assembly line.

We will be sharing more through video and other content in the coming weeks. We are incredibly excited to take you along this journey with us.

-Brian Riley

CEO and Co-Founder

Guardian Bikes